Development of Mattress High-Speed Dryer (MHD4)

Facility Overview

Mattress High-Speed Dryer (MHD4) dries cleaned and water removed 4 sheets of mattresses in short time and with low running cost as well.

If it is fiber product, the mattresses will completely be dried within 45 minutes as minimum and urethane product will completely be dried within 60 minutes as minimum also.

Note-1: Result (time) Display from Experimental Value of Our Company: Less than 30% of Moisture Content Ratio

Note-2: Slight operation time variation exists depending on target product and operating seasons.

Note-3: MHD4 is the abbreviation of Mattress High-Speed Dryer 4

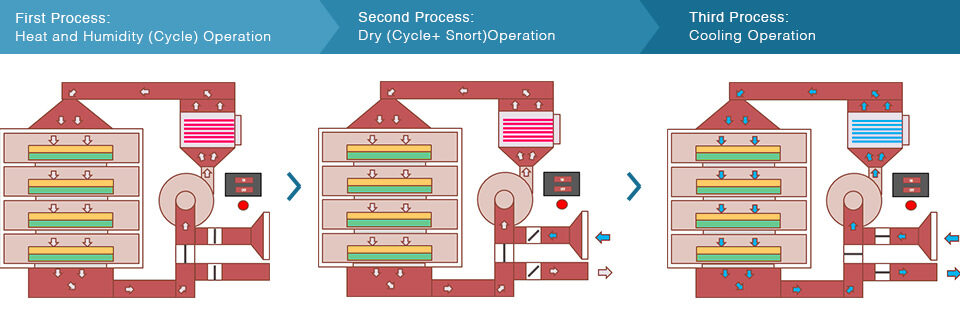

High temperature and high humidity statuses are created by [Heat and Humidity Cycle Operation] which feeds inside air to heated heat source (Electric Heater) repeatedly. Promotion of evaporation [Drying] by high temperature and [Sterile Filtration Effect] by high temperature (Wet Type) are realized simultaneously.

The 4 sheets of mattresses are dried simultaneously as well as evenly by discharging inside circulated air, performing proper damper control, taking external air in and feeding dry heated air.

Stop heat source (Electric Heater), blow in only external air and get the temperature of mattress down to the temperature for easy taking out. In addition, dew condensation is prevented by leaving mattresses after taking out as they are warm.

Development Background

Tanabe Engineering Corporation has considered something helpful by integrating our company’s technology toward aged person/ the welfare industry in these days as the population ages and fewer babies are born. Our company has turned our attention to bed where those who require nursing care spend long time, specifically mattress where body contacts, our company has applied the technology for [Thermal Machine/ Dry] to mattress maintenance and linked to commercialization.

Expected Applications/ Effects

Our company will contribute to the following points with [Dry] which takes time (Time and Effort) and cost other than [Washing] mattress.

1) Reduce the introduction cost of customer by adopting an electric heater

2) Short-time drying is realized by the structure - automatic control to make mattress inside temperature rising quickly

3) Heater control to aim low running cost [SSC: Solid State Contactor]

4) Adoption of touch panel easy to use by anybody

5) Adoption of [Heat and Humidity Cycle Operation] by which the same effect as wet sterilization is obtainable