KMA ULTRAVENT® Air extraction and filtration systems

Clean Air KMA ULTRAVENT

Exhaust air purification with KMA ULTRAVENT®

Nowadays, foundries are confronted with strict regulations in terms of occupational health and safety as well as environmental protection. Additionally, the climate protection wins more and more attention as well as becoming a third objective in industry. The reason for this purpose is that companies are increasingly involved in international future actions for reducing CO2 emissions.

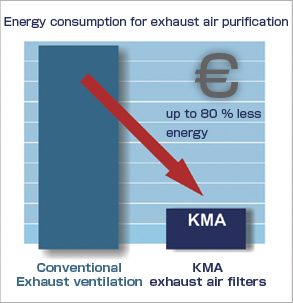

KMA ULTRAVENT® exhaust filter systems accommodate these requirements already: they are suitable for the separation of oily, greasy or pasty aerosols from the exhaust air and are characterised by high separation efficiency, durability and very low energy consumption. Due to the integrated heat recovery technology-which can be combined with highefficiency heat pump if necessary - the foundry can also handle ambitious goals for improving its carbon footprint and put energy savings up to 70-80% into practice compared to conventional exhaust air technology.

Reducing costs - in recirculating or exhaust air mode

ULTRAVENT® exhaust air filter systems allow the purification of the indoor air in energy-saving manner: High energy efficiency can be achieved in a recirculating air mode as well as in an exhaust air mode. Exhaust air blowers and excessive heat loss can be avoided during the heating period by the recirculating air mode, because the filtered air is returned to the working place. During the exhaust air mode, however, large amounts of energy can be recovered and be used for follow-up processes through the installation of a highly efficient heat recovery system. In both cases, the total energy consumption of conventional exhaust ventilation systems decreases up to 80% by using ULTRAVENT® air filtration technology. In addition, buildings and machines stay clean - resulting in lower maintenance and cleaning costs.

KMA ULTRAVENT® filters are characterized by the following features

+ Cost-effective operation through wear-resistant filters and low energy consumption

+ Minimised maintenance due to highly effective automatic filter cleaning

+ Flexibility through a modular system with many different sizes

+ Durability: filter housing and collection cells are made from stainless steel on request

Centralised or decentralised?

KMA ULTRAVENT® filtration systems allow centralised or decentralised extraction concepts. In the decentralised extraction concept each machine is equipped with a KMA exhaust air filtration system. Here, no expensive and complex exhaust pipes are required and the operation remains flexible, if there is any planning about future machine enhancements. In a centralised extraction concept several machines are connected to a single filtration system. The investment costs for a centralised filter are usually lower than for several smaller filter systems. However, the cost of pipelines must be taken into account.

Flexible and modular

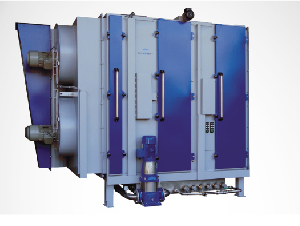

ULTRAVENT® exhaust air filtration systems are designed modular and flexible: Depending on the type of emission ULTRAVENT® can be equipped with demisters, electrostatic filter units, heat exchangers as well as heat pumps. Retrofit kits for subsequent modifications are available as well. KMA ULTRAVENT® has a wide range of standardised, modular hoods. The modular system allows here for individual adaptions at the site of operation as well.

KMA ULTRAVENT® exhaust filtration systems are available in different sizes. The module sizes are staggered and aimed at the exhaust air volume, which needs to be purified. The largest module unit has an air capacity of 30,000 m3/ h. ULTRAVENT® systems are characterised by a compact design. At higher air quantities, two or more filter modules are simply connected side by side.